Brand:aa

Product detail:

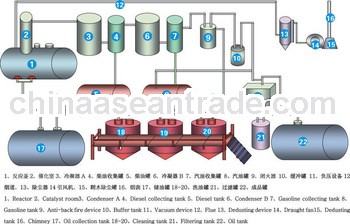

WASTE TIRE PYROLYSIS MACHINERY TO GET FUEL OIL

Waste or Treasure?

Waste tire, waste plastic, waste rubber, waste oil etc. are increasing every moment.

At the same time, oil resources are decreasing every single day.

How to deal with these problems?

We use green technology recycling waste to oil resources.

We are specialized in manufacturing pyrolysis machine for recycling waste tires, waste plastic, waste rubber etc. and distillation machiner for recycling waste oil, crude oil, black oil etc.

Approx oil yield of different raw materials

PE | 95% |

PP | 90% |

PS | 90% |

ABS | 40% |

Leftovers of paper | Wet 15-20%, dry 60% |

House garbage | 35-50% |

Plastic cable | 80% |

Plastic bag | 50% |

Submarine cable | 75% |

Rubber cable | 35% |

Sole | 30% |

Big tires | 45-50% |

Small tires | 35-40% |

PVC | Not suitable |

PET | Not suitable |

Product features

- Unique design of reactor guarantee the service life and safety.

- No need to crush tires. We can feed whole tires into the reactor. Save manpower and increase efficiency.

- Electric cabinet help you watch the temperature and easy to control power.

- Technical condensers and circulating water guarantee the cooling effect and improve oil yield.

- The residual gas (tail gas) recycle to furnace as fuel. Save energy.

- Flue gas is processed by dust removal device. Reach the emission standard.

- Experienced engineers will help you install the machine and train your workers.

Model (diameter*length) (mm) | 2200*6000 | |

2200*6600 | ||

2600*6000 | ||

2600*6600 | ||

2800*6000 | ||

2800*6600 | ||

Boiler plate | Q245R/Q345R | |

Thickness | 12/14/16/18mm | |

Condensers | Vertical condenser | |

Horizontal condenser | ||

Product series | 4th generation | |

5th generation | ||

Slagging system | Bucket elevator | |

Carbon black vacuum | ||

Final product (take tires for example) | oil | 45-50% |

Carbon black | 25-30% | |

Steel wire | 10-15% | |

gas | 5% | |

Total weight | 30-35T | |

Total power | 19kw | |

Space needed | 150m2 | |

Labor needed | 4 workers | |

We have the 18years history,we have waste tire refining oil equipment,waste plastic refining oil equipment,waste tire and plastic all-in-one refining equipment.

over the years,we joint scientific department and in more than well-known exports and scholars,Continuously improve our technical strength.recently,we have 6 R&d engineers and 20 technical personnel,the products is full automatic continuous production,and have full automatic feeding and full automatic slagging .

the environmental friendly is one of our high technology,Using this equipment ,main would produce water, sound ,slag,waste gas,through our patented products: recycling pool,Sulfur removal system,full automatic slagging system,and The noise static special treatment, all can meet the national discharge standards,no pollution.and our carbon black is deep processed through Slag refining equipment .the customer bought our equipment all can safe and relived to produce,and get their Using this equipment ,main would produce water, sound ,slag,waste gas,through our patented products: recycling pool,Sulfur removal system,full automatic slagging system,and The noise static special treatment, all can meet the national discharge standards,no pollution.and our carbon black is deep processed through Slag refining equipment .the customer bought our equipment all can safe and relived to produce,and get their consistent high praise.

1.security:our equipment have anti-blocking device,also have pressure gauges,alarms,safety valves and vacuum equipment

Safety

1) Pressure gauge, alarming device, safe valve.

2) We have anti-clogging device, in case of jam, there will be antomatic alaiming, automatic exhaust and automatic decompression.

3) Using 245R/345R boiler plate or 204/205 stainless. The thickness of part by fire is 14/16/18mm, other parts is 12mm.

4) Automatic welding, processing according to standard of head of pressure vessel.

5) With proprietary vacuum system, it is much safer on condition of negative pressure.

Energy saving

1) Exhaust gas recycle to furnace.

2) Continuous feeding with automatic feeder, no gas leak.

Environmental protection

1) Built-in slagging, seal with water, no solid pollution.

2) With dust removal equipment there is no air pollution

Specification of Equipment

Items | Contents | ||

Raw material | Waste tyres, scrap plastic, waste rubber | ||

Structure form | Horizontal | ||

Model | DT-6T | DT-8T | DT-10T |

Size of reactor | D2200mm*L6000mm | D2600mm*L6600mm | D2800mm*L6000mm |

24-hour capacity | 6 tones | 8 tones | 10 tones |

Operating pressure | Constant pressure | ||

Heating material | Coal, charcoal, fuel gas, fuel oil | ||

Average out-put oil rate | 45%-50% | ||

Material of reactor | Q245R/Q345R boiler plate | ||

Thickness of reactor | 16mm | ||

Rotate speed of reactor | 0.8 turn/minute | ||

Mode of cooling | Water cooling | ||

Power in total | 20 Kw | ||

Life | 5-8 years | ||

|

| ||