Product Descript ion

Packaging systems

Canton Fair

Our advantages

After 10 years of development,Kenwei has become one of the largest manufacturing base of

producing professional combination weigher (linear weigher / check weigher / meta l detector, etc.) in the

world with widely influence.

world with widely influence.

1.Brand:

A.In 2007,Kenwei was awarded the "Technology Innovation Award" form Chinese food

processing and packaging industry by "stable time development model".

B.Kenwei was granted as the Industry-University-Research combinationAwards in combination weigher field.

C.In 2016,Kenwei was granted as the high-technology enterprise

2. Products:

A.Products: Currently only a few combination weigher manufacturing enterprises such as Ishida,

Kenwei who uses "stable time development model" in program design and development.This

development model is the core element to ensure weigher be in long-time stable operation and make

material saving maximize.

BAdvantages: The main advantage is reflected in weighing accuracy,which indicates that the average

error between actual weight and displayed weight is smaller, it could help customers save materials;

The same interval time for hopper doors repeat open and close make vibration torque consistency,

which make the mechanical structure mutual friction loss is minimized and machine can be in

long-term stable operation.

C.Accuracy:Taking into consideration that the mode of main vibrator and linear vibrator and

vibration absorption ability of the

independent research and develop both standard and high amplitude vibrators to meet the needs of

different materials.Also control the vibrating time and amplitude separately by control systems to

automatic adjust the linear vibrator amplitude,which make the material flow optimization;

middle base of machine case,we always use 2.5mm-3.0mm stainless steel sheet and strengthen internal

structure by providing reinforcement to ensure the machine's rigidity.Some models take the machine

case and middle base integrated, through a combination of AD converter module and anti-jamming

technology,which effectively reduce the vibrating interference and ensure the accuracy of machine

running.

D.Molds and components:Key components such as hoppers, vibrating pans, waterproof cover are

made by high-precision molds,which have high consistency and interchangeability;Sensors we use is

from Japan and Germany well-known brand; Circuit board is in excellent industrial-standard

design, which the chip selection, PCB design and protection are based on the industrial-grade

materials and the production process.

E.Individual needs: Kenwei develop a variety of weighers for different material, including counting

weigher (pouch fill into a large bag), noodle weigher, weigher for frozen food, feeding-control

weigher, weigher for stick-shaped products, cheese weigher,salad weigher,mixing weigher,etc.Above

products can be selected for digital and modular, single or multi discharge chutes, "high precision"

and "high speed" can be freely selected, etc., including self-developed software system in order to

better meet the individual needs of different clients.

F.Function:More diverse function , more convenient operation,such as easy cleaning, simulation

tests, free output ports,timing hopper for choice,etc.HMI uses standard Modbus protocol, fully

compatible with the industry standard, and easily achieve real two-in-one packaging machine

Interface.

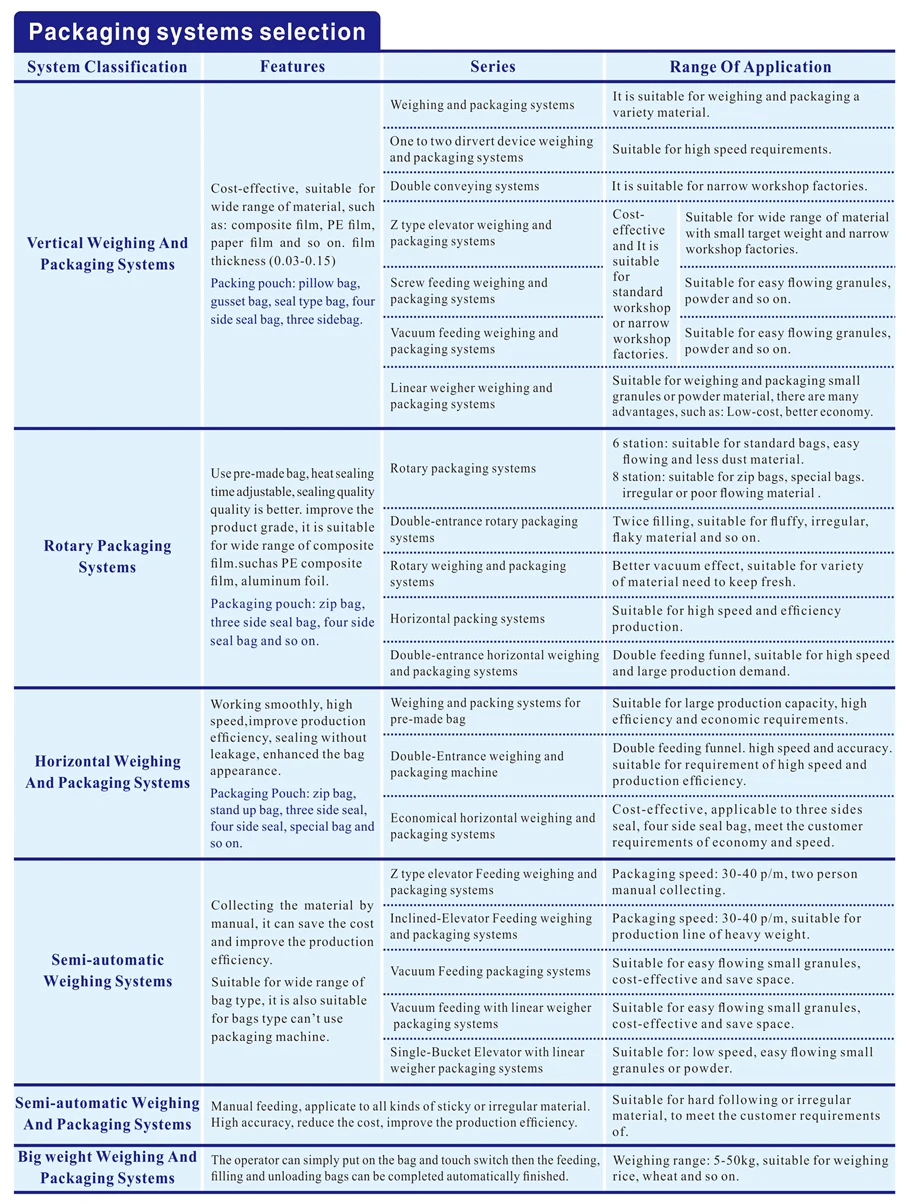

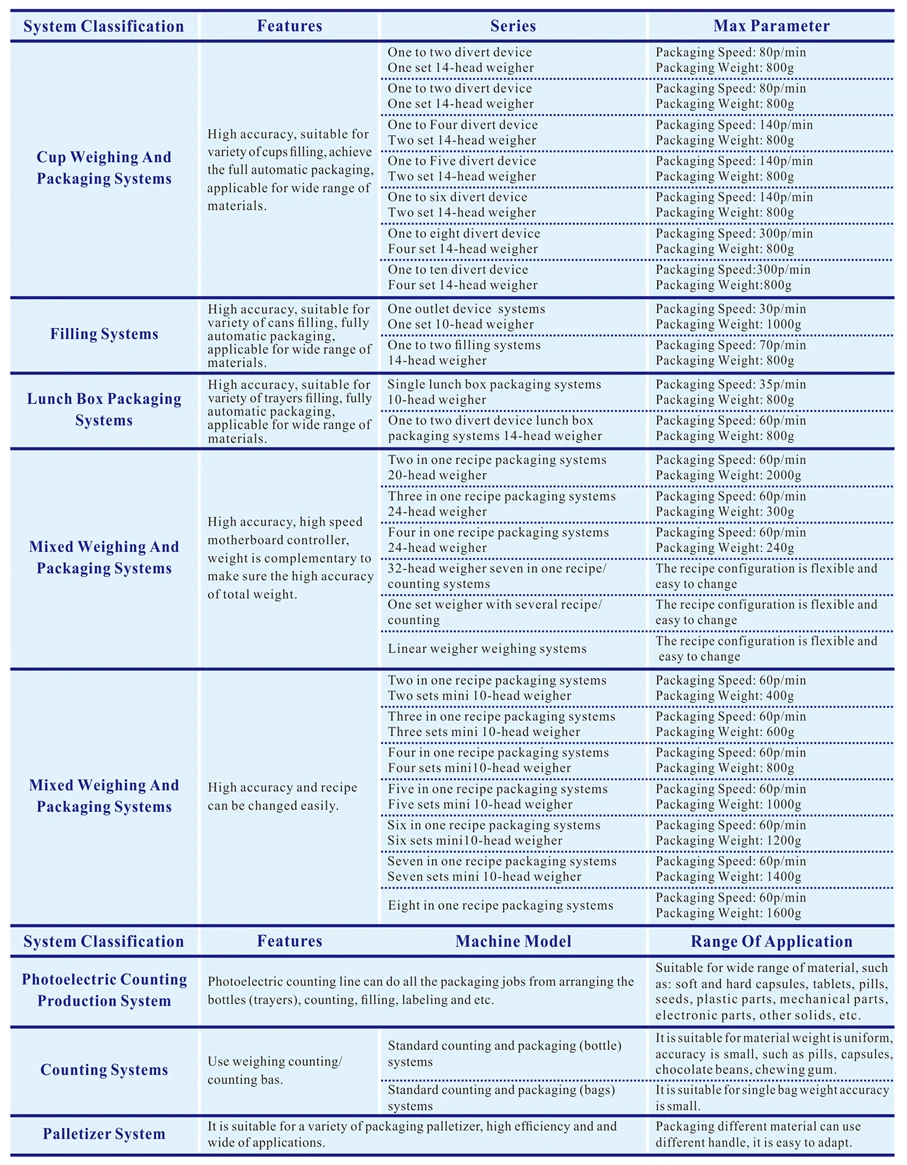

1.Weighing packaging system (production line) mainly including the following two equipment:

1)Weighing machine(such as multihead weigher): Weighing machine configuration determines the system's economic performance, cost savings and efficiency;

2)Packaging machine:filling material and forming the bag,it determines the beauty and solid of the bag.

2.Weighing and packaging production line suppliers are as following:

1)Weighing machine manufacturers

2)Packaging machine manufacturers

1)Weighing machine(such as multihead weigher): Weighing machine configuration determines the system's economic performance, cost savings and efficiency;

2)Packaging machine:filling material and forming the bag,it determines the beauty and solid of the bag.

2.Weighing and packaging production line suppliers are as following:

1)Weighing machine manufacturers

2)Packaging machine manufacturers

CERTIFICATES

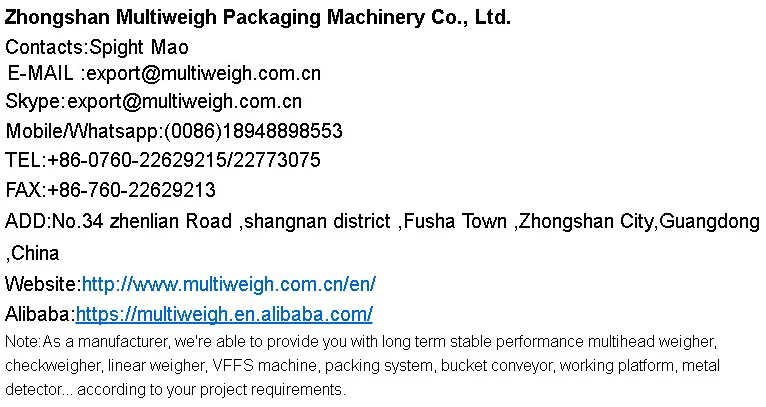

Contact us

Googole Maps:

Product Catalog:(You can tailor it to your needs)

Multihead Weigher

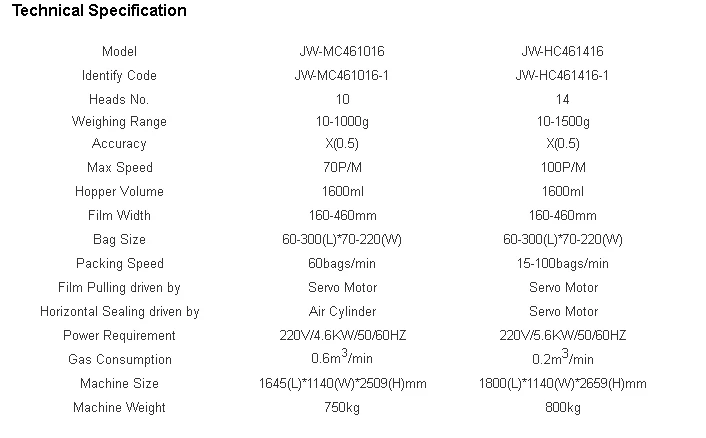

Combined Weighing And Packing Machine

Linear Weigher

Check Weigher

Loss-In-Weigher Feeder

Accessories