This series of high speed slitting line (120m/min

Features

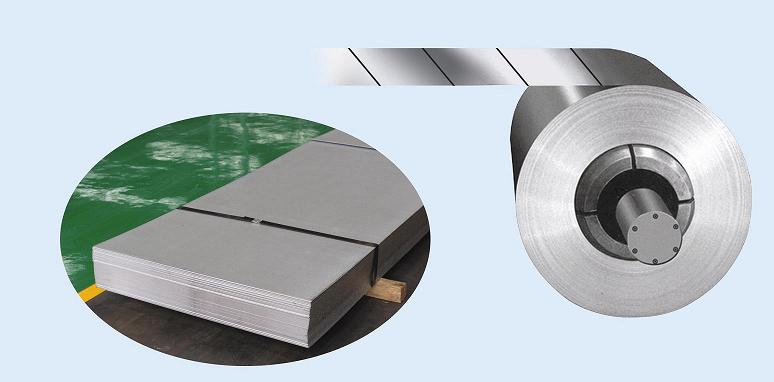

This Steel Coil Slitting Line is adaptable to process cold-rolled and galvanized coils, silicon steel coil, stainless coils, pre-painted coils, aluminum coils, and all sorts of plate and coated coils. And it is widely applies to many industries like automobiles, containers, household appliances, food packing, construction material etc.

This line consists of coil lifter, decoiler, slitter, scrap recoiler, damping device, recoiler etc, accompany of feeder, loop bridge, pinch etc.

It has advantage such as proper layout, easy operation, highly automated and high production efficiency.

Complete two slitting machines is optional. When one slitting machine is working, the other one can change blade spacer and sleeve or maintenance and repair, it can improve working efficiency, increase production and decrease cost.

Features

This Steel Coil Slitting Line is adaptable to process cold-rolled and galvanized coils, silicon steel coil, stainless coils, pre-painted coils, aluminum coils, and all sorts of plate and coated coils. And it is widely applies to many industries like automobiles, containers, household appliances, food packing, construction material etc.

This line consists of coil lifter, decoiler, slitter, scrap recoiler, damping device, recoiler etc, accompany of feeder, loop bridge, pinch etc.

It has advantage such as proper layout, easy operation, highly automated and high production efficiency.

Complete two slitting machines is optional. When one slitting machine is working, the other one can change blade spacer and sleeve or maintenance and repair, it can improve working efficiency, increase production and decrease cost.

Machine Configuration

|

No. |

Item |

Qty |

|

1 |

Storage Platform |

1 pcs |

|

2 |

Coil Lifter |

1 set |

|

3 |

Hydraulic Cantilever decoiler |

1 set |

|

4 |

Snubber Roller |

1 set |

|

5 |

Pinch roll & leveler |

1 set |

|

6 |

Shearing machine |

1 set |

|

7 |

Loop bridge NO.1 |

1 set |

|

8 |

Side Guide Roller |

1 set |

|

9 |

Slitting Machine |

1 set |

|

10 |

Pressing Device for Tail Tension Plate |

1 set |

|

11 |

Scrap Recoiler |

1 set |

|

12 |

Loop bridge NO.2 |

1 set |

|

13 |

Separating Device |

1 set |

|

14 |

Damping Device |

1 set |

|

15 |

Pressing Device |

1 set |

|

16 |

Recoiler |

1 set |

|

17 |

Hydraulic Support Arm |

1 set |

|

18 |

Unload Cart |

1 set |

|

19 |

Hydraulic + Pneumatic System |

1 set |

|

20 |

Electric System |

1 set |

Technical Parameter

|

Material |

Cold rolled steel coil ; Galvanized steel coil Pre-paint steel coil; Stainless steel Coil |

|

Thickness |

0.3-3.0mm |

|

Width |

1000 / 1250 / 1300 / 1500 / 1600 / 2000mm |

|

Weight |

10 / 15 / 20 / 25 T |

|

Speed |

0~120m/min |

Photos for Reference